A cutting‑edge autonomous parcel sorting facility has officially begun operations in Argentina, marking a major milestone in the modernisation of logistics infrastructure across Latin America. The new centre — the first of its kind in the region — is equipped with a fleet of autonomous robots that dramatically increase parcel handling capacity and accelerate processing times.

Located at a major logistics hub near Buenos Aires, the facility spans more than 1,180 square metres and employs 240 autonomous sorting robots. The system is capable of handling up to 9,000 parcels per hour, a throughput roughly three times higher than the site’s previous configuration. Designed mainly for small and medium‑sized parcels weighing up to 5 kg — which represent the bulk of e‑commerce shipments — the robotic installation supports both domestic and international flows.

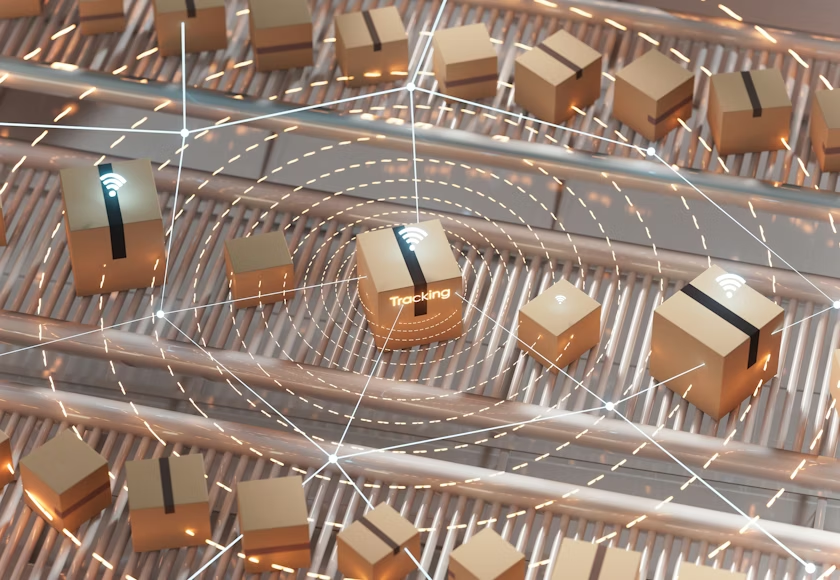

The sorting solution integrates artificial intelligence, advanced sensor networks and dynamic routing algorithms to deliver rapid, accurate parcel distribution. Parcels are inducted through multiple workstations, scanned via barcode or QR code recognition, then transported by autonomous mobile robots to more than a hundred output chutes serving destinations across the metropolitan area and beyond.

Officials involved in the project say the deployment underscores a broader shift toward intelligent intralogistics, where robotics and data‑driven systems are central to meeting rising demand and improving operational efficiency across parcel networks. The modular design of the system also means additional robots or output destinations can be added with minimal disruption, providing scalability as volumes grow.

Plans are already underway to expand the hub’s capabilities further in 2026, with the introduction of larger parcel sorters, RFID‑based tracking and additional automated handling systems that extend automation deeper into the supply chain.

#BreakingNews #SupplyChainNews #LogisticsUpdate #AutomationInLogistics #RoboticsRevolution