A new automation ecosystem initiative in the Netherlands is attracting logistics and warehouse technology innovators, aiming to create a centralised test and demonstration hub where suppliers and operators can showcase, trial and adopt cutting-edge automation solutions under one roof. The project is designed to help speed up intelligent automation deployment across materials handling, fulfilment and intralogistics operations — a key priority as companies grapple with labour shortages and high throughput demands.

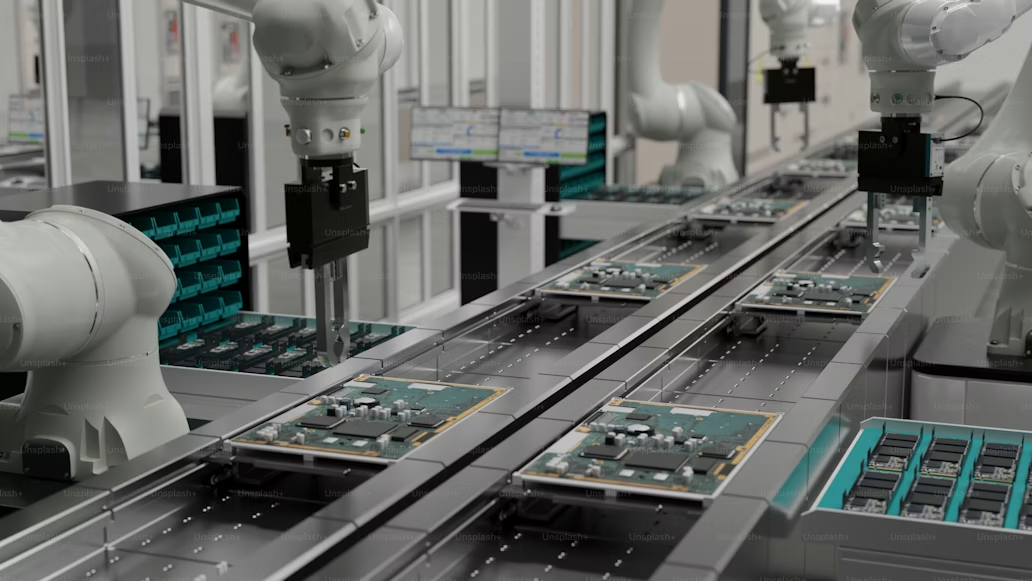

The InnoScale automation centre — backed by European distribution and logistics organisations — will host a wide range of automated technologies, offering up to two examples of each category of system available on the market, from robotics and shuttles to warehouse software platforms. This “ecosystem” approach gives buyers the opportunity to compare systems directly and develop implementation plans before committing to full-scale investment, reducing risk and shortening deployment timelines.

Importantly, the facility is structured to support innovation partners and new entrants, offering services such as legal, marketing and technical support to firms entering the European market. Participants will be able to demo, test and benchmark automation hardware and software in realistic operating environments, fostering collaboration between solution developers and logistics buyers.

Industry leaders say that such ecosystems help overcome traditional barriers to warehouse automation — including high upfront costs, integration challenges and uncertainty over return on investment — by providing a one-stop hub for evaluation, customisation and support. Advocates predict this model could become a global template for accelerating automation adoption and strengthening supply chain resilience in the face of evolving e-commerce demands.

#BreakingNews #SupplyChainNews #WarehouseAutomation #LogisticsInnovation #AutomationEcosystem