Businesses and supply chain leaders are already feeling the impact of looming new tariff threats on international trade, which are prompting companies to adjust ordering, inventory and logistics strategies in ways that are reshaping global supply chains. Experts describe how tariff uncertainty — even before duties are officially imposed — can have real operational and financial consequences for logistics planning and execution.

Industry observers note that the prospect of tariffs on key trading partners has slowed U.S. import activity, as some shippers pause orders to avoid higher duties, while others accelerate shipments ahead of potential changes. This has led to stockpiling of critical components, filling warehouses with inventory ahead of anticipated tariffs — often at the wrong points in the network and at the wrong times for efficient supply chain flow.

The threat of tariffs also contributes to customs delays and planning disruptions, as supply chain teams struggle to predict delivery timing and compliance requirements for goods that may soon face higher levies. This logistical uncertainty can ripple across transport, warehousing and distribution networks, increasing costs and reducing flexibility.

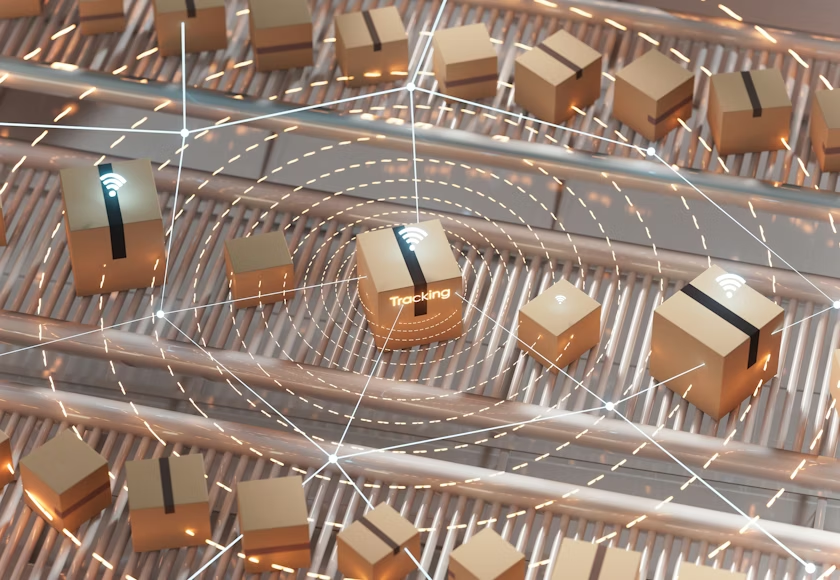

Analysts emphasise that tariff threats reduce visibility and predictability, two key pillars of effective supply chain management. Companies are being forced to prioritise enhanced data and warehouse visibility to make faster, more informed decisions when sourcing, routing and inventory planning — essential steps to mitigate potential tariff‑driven disruptions.

Across industries, the fear of higher import costs and cross‑border trade barriers is reshaping sourcing and logistics strategies, prompting many organisations to reconsider supplier locations, reroute supply chains around vulnerable nodes, and evaluate alternative trade routes or partners to maintain continuity and control costs.

#Breakingnews #SupplyChainNews #TradePolicy #LogisticsUpdate #GlobalSupplyChains